|

Modular Synthesis, LLC |

|

I spent 34 years at Tektronix working in all parts of the company - computer graphics, video and networking, and test and measurement (my professional information is on my LinkedIn page). I've since retired to enjoy my hobbies and I now have the time to devote to my music projects. I have the time and interest to be able to help and assist fellow Synth-DIY'ers with their projects and formed Modular Synthesis, LLC to help. I am on www.getrecommended.com

Many of the items that are sent to me for repairs are old and have limited or no technical documentation. Some of the parts are unobtanium or fragile. If parts are not available, I may be able to modify the design to use different parts. However, when I am working on a vintage repair, one of four things can happen:

1. I can work on it and am unable to repair it.

2. I can work on it and something else can go wrong.

3. I can work on it, repair it, return it, and it can break again, possibly soon.

4. I can work on it, repair it, and it will work fine.

I have had only two products that I have been unable to repair and they were both mine. One is my second Peavey DPM-C8 with a lot of PCB damage. I haven't given up yet but need to ohm out the entire PCB. The other was a keyboard with flex circuits that deteriorated. I managed to repair some of them with silver conductive paint but decided it just wasn't worth the effort to complete. I do keep you informed via email of my progress and you can direct my repairs to minimize cost.

For DIY repairs, the number one problem I find is soldering issues - unsoldered pins, incomplete soldering, or solder bridges. You have to wash and carefully inspect every pad with magnification to find these. I have added tips and information on my Modular Synth Tips page for soldering, cleaning, and inspecting PCBs as well as proper packing for module shipment. Hopefully these tips may save you some time and grief. Unfortunately I also encounter design errors and insufficient margin as well. These do take more time to find and correct.

This service is my "hobby" and my low rate of $35/hour is to give back to the community. So, I am not interested in the following:

A. Don't buy a basket case item that is rare and valuable so you can have me restore it and with my rates you come out ahead.

B. Don't have me build you a module so you can then turn around and sell it.

C. Don't have me repair your broken stuff so you can immediately sell it.

D. If I design you something custom I give you the documentation so you can maintain it. Don't give my designs away or make them public.

If you are a non-USA customer, I will ask you to handle the return shipping. These forms take time, I sometimes do not understand all the address implications, and most likely will have to fill out customs forms. That takes additional time and energy that I am not compensated for. And, do NOT fill out the custom forms with some lower repair amount. I treat this as a legitimate business with a license, insurance, and taxes. I will NOT ship with falsified documents. If you send me custom forms that do not match my invoice, I will simply not ship and you forfeit your repair item. Sheesh, did I really have to clarify this?

I will sometimes do builds. I prefer to have you source most/all of the parts. I no longer will do large builds (Buchla 208, 212, 248, etc.) as with age comes physical issues with significant repetitive hand motions.

Items not paid for or no communications for 30 days after a repair is completed, unless previously arranged, will be considered abandoned. I reserve the right to sell abandoned items to recover my cost of repairs. I'm sorry, but after spending time repairing your item I don't have the space or funds to store your item indefinitely. If you can't afford to have it fixed, don't send it to me.

Contact me if I can consult or be of help or assistance with your project, repair, design, or restoration.

| I have recent experience repairing these modules and music equipment: (I've since stopped updating this list ...) | |

|

Analog Systems RS-290 Aries AR-312 EG, AR-314 VCF, AR-316 VCA, AR-317 VCO, AR-318 S&H, AR-324 dual LFO, AR-328 spring reverb and output, AR-332 Dual VCO ARP avatar, odyssey, and sequencer, ARP-4072 clone VCF ASM-1 VCO option 3 Barton Quad VCA Blacet time machine Boss DDR-55 drum machine Buchla 208 music easel, 216 touch controlled voltage source, 227 system interface, 230 triple envelope follower, 245 sequential voltage source, 258 dual VCO, 259 complex oscillator, 266 source of uncertainty, 277 signal delay, 281 quad function generator, 285 frequency shifter, 291 dual voltage controlled filter, 292C quad low pass gate, 294 comb filter, 296 programmed spectral processor, RSF Kobol dual vco, 402 quad dual lfo CGS Bi-N-Tic filter, CGS-26 cv processor, CGS-29 wave multiplier, CGS-31 digital noise, CGS-35 Synthacon VCF, CGS-48 VCO, CGS-49 wasp filter, CGS-58 utility LFO, CGS-62 slope detector, CGS-113 wavefolder, CGS-114 dual universal slope generator Cyndustries QLPG Digitech MSP-4 Doepfer A-138 matrix mixer EFM Bassace monosynth Elby ASDR Electro Harmonix pedals EMU Drumulator Ensoniq EPS-16+ and mirage keyboards Experience effects pedal Feedback Modules Two59 Fender most anything vintage ... Fenix II Fonitronic MH21 Triple Resonator and ALM003 SID GUTS Fostex 3180 reverb Fritz 5pulser, threeler filter, TZ-FM VCO Greistleizer effects pedal Hexinverter SimpleSEQ Jürgen Haible polymoog resonator, tau phaser, vibrato scanner, frequency shifter, variable slope filter/phaser JVC TT-81, TT-101, and TT-801 turntables L-1 VC Resonant EQ Loft 450 delay/flanger Milton sequencer "Miss Ten" VCF/VCA Modcan 4075 VCF Moog 901 VCO, 901A & 901B VCO, 902 VCA, 903A Noise, 904A, 904B, & 904C VCF, 905 reverb, 907 fixed filter bank, 911 EG, 911-A dual trig, 912 EF, 914 fixed filter bank, 921 VCO, 921A & 921B VCO, 960, 961, & 962 sequencer, 984 four channel mixer, 992 control voltages, 993 trigger and envelope voltages, CP-2, CP-3A, CP-4A, CP-8A, 961CP, 930 power supply, 951 keyboard Moog Micro, Source and Sonic Six Oakley SVCO, ADSR/VCA, TB-3030 Oberheim SEM PAiA 2700 and 4700 modules, MIDI2CV Papareil Polivoks filter and quantix8 Peavey DPM4 & DPM-C8 keyboards René Schmitz MS20 filter Roland RE-301 chorus-echo, 112 2VCO, 140 2ENV-LFO, 172 Phaser Shifter/Audio Delay/Gate Delay Sequential Circuits Inc model 700 programmer, model 800 sequencer Serge modules Sony TA-E88 preamp, TAN-511 amplifier Sputnik Modular (many modules) Tellun TLN-156 reverb Thomas Henry X-4046 VCO TTSH Yamaha DX7 keyboard Yocto TR-808 clone YUSynth S&H, ARP4072 filter Wasp synth Wersi CX-2 rhythm & accompaniment Wiard JAG ... and of course any modules I have built and my instruments that I have repaired |

|

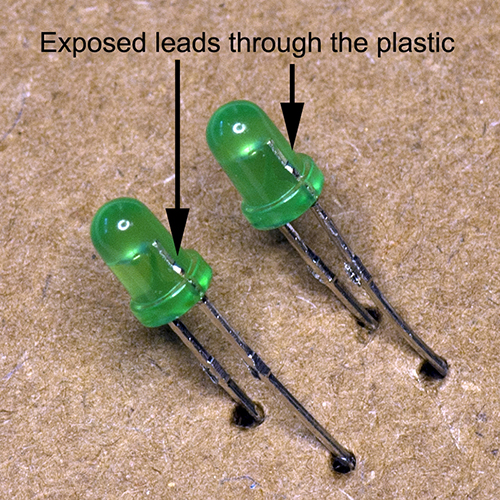

Here is one of my more bizarre repair finds. This was in a Buchla 25S and the CMOS logic kept failing after a short time. The leads were not fully encapsulated in plastic and would intermittently short to the panel!

Here are some sample projects that I have helped with.

|

|||||||||||||||||||||||||||

|

|||||||||||||||||||||

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||

|

|||||||||